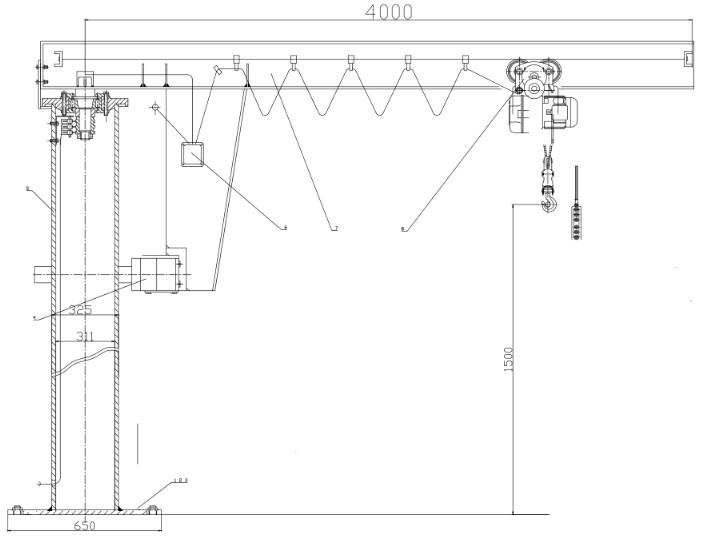

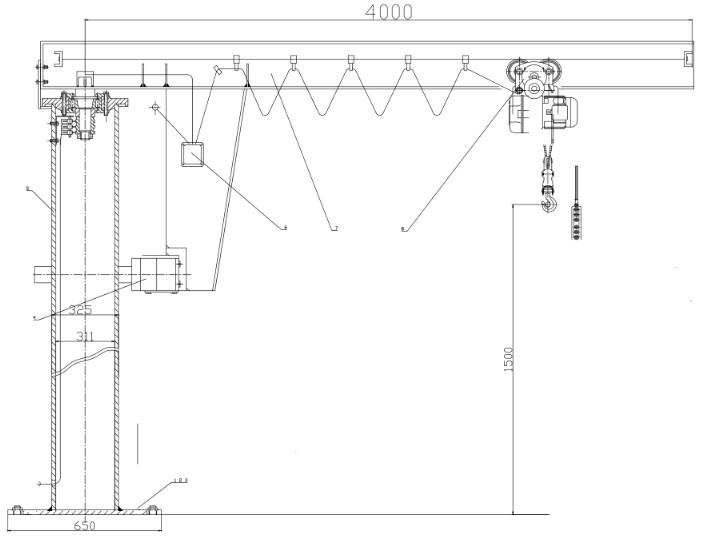

Best Price Electric Fixed 5 Ton Column Slewing Swing Jib Crane

Design Manufacture

Product description

BZ type column cantilever crane is a cost-saving comprehensive

processing system. In some cases, this processing equipment is

usually the most economical solution.

This applies to storage yards, loading ramps or buildings where

other equipment cannot be installed due to structural restrictions.

BZ type column cantilever crane (maximum weight 1000kg)

Slewing cranes are characterized by high load capacity and

abduction relative to their own weight.

The light weight allows the cantilever to move easily, and the use

of hollow section rails as crane beams can provide very low moving

force.

BZ type column cantilever crane (up to 2000 kg)

Lightweight design and low headroom boom make this column slewing

boom crane suitable for general-purpose applications up to 2000 kg

in the medium load range.

BZ type column cantilever crane can also adopt low headroom design

The lower headroom size leads to a standard design with a 290 mm

increase in lifting height.

Whether it is for low-altitude space applications, modernization

measures or changes in building use, our "short" units are the

perfect solution in many situations.

Product advantages

1. Stable base: fixed with multiple chemical expansion screws, not

easy to rust, increase the force area, and ensure safety.

The bearing surface varies with tonnage.

2. Rotation angle: The rotation angle can be 360 degrees to meet

the needs of different space environments.

3. Smooth operation, low noise: The machine runs smoothly, with low

noise, flexible operation, and convenient installation and use.

4. Energy-saving, energy-saving, time-saving and labor-saving:

small floor space, convenient operation and maintenance.

It is an energy-saving material lifting equipment.

Use maintenance techniques

1. The operator shall strictly abide by the crane operating

regulations and shall not overload it.

2. The terminal baffle is not allowed to be used as a normal

parking method.

3. The chain or steel cable of the heavy object must be strong

enough and fastened firmly.

4. Lifting and moving of heavy objects should be carried out in a

vertical state.

It is prohibited to use electric hoist to drag or forcibly lift

buried heavy objects.

5. It is strictly forbidden to stand on the top to lift heavy

objects, and to walk on the bottom.

6. After work or rest, do not hang heavy objects in the air.

Technical parameters

| Model | BZ0.5 | BZ1 | BZ2 | BZ3 | BZ5 |

| Lifting capacity | T | 0.5 | 1 | 2 | 3 | 5 |

| Max. Lifting height | M | 3 | 3 | 3 | 4 | 4 |

| Max. Horizontal throw | M | 2.6 | 3-4 | 2.9-3.9 | 3.8 | 3.7 |

| Max. Radius of gyration | M | 3.6 | 4-5 | 4-5 | 5 | 5 |

| Max. Rotation moment | T/M | 3 | 6 | 12 | 18 | 27 |

| Angle of revolution | Degree | 360 |

| Lifting speed | Normal | m/min | 8(4) |

| Slow | m/min | 0.8(0.4) |

| Traveling speed | m/min | 20 |

| Angle of revolution speed | m/min | 1 | 0.75 | 0.7 | 0.9 | 0.6 |

Packaging